In the present study therefore the isf process is performed on a polymer sheet by varying the plastic strain ranging from 6 to 108.

Incremental sheet metal forming advances and challenges.

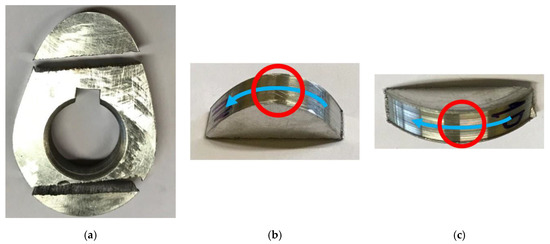

Positive die less incremental forming also referred to as two point incremental forming tpif is another variant of ismf and is known to be first attempted by matsubara in this process fig.

The die less nature in incremental forming provides a competitive alternative for economically and effectively fabricating low volume functional sheet products.

The innovative incremental sheet forming isf process affects the post forming properties of thermoplastic polymers.

Advances and challenges in sheet metal forming technology t.

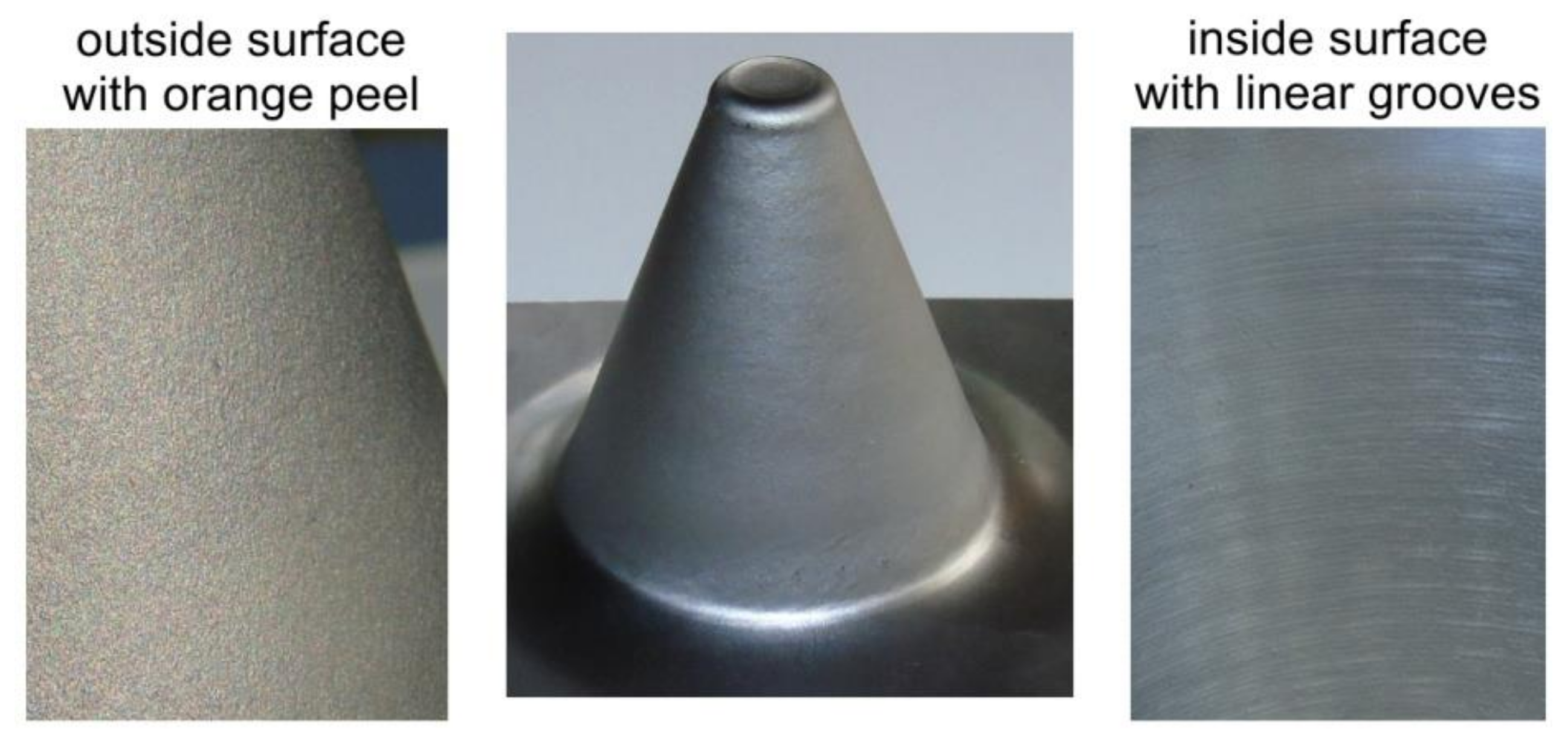

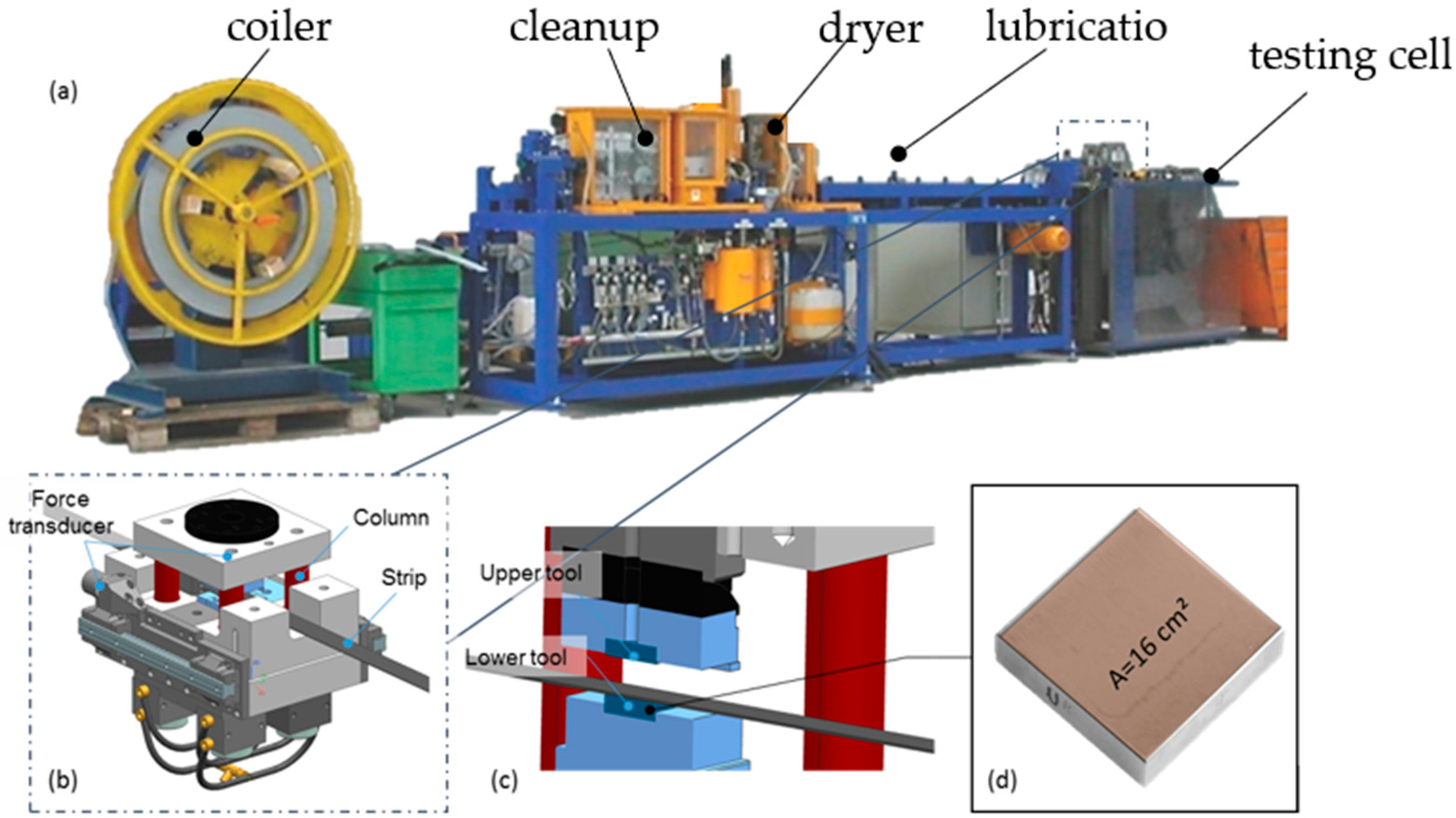

The process locally deforms sheet metal using a moving tool head achieving higher forming limits than those of conventional sheet metal stamping process.

Abstract requirements for light weight and crush resistance vehicles require the use of ahss dp trip twip and.

International conference on technology of plasticity gyeongju korea pp 1967 1982 google scholar.

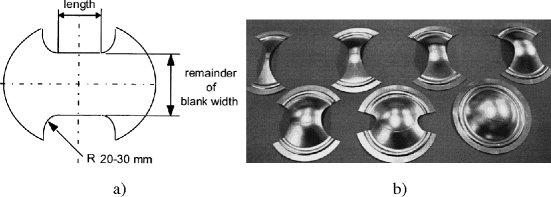

Incremental sheet metal forming has demonstrated its great potential to form complex threedimensional parts without using a matching die.

However studies have shown that it can be applied to polymer and composite sheets too.

Incremental sheet metal forming has demonstrated its great potential to form complex threedimensional parts without using a matching die.

Cao j huang y reddy nv malhotra r wang y 2008 incremental sheet metal forming.

However the effects of degree of plastic strain and the orientation and size of specimen on the mechanical properties are still unknown.

The tool which can be attached to a cnc machine a robot arm or similar indents into the sheet by about 1 mm and follows a contour for the desired part.

Single point incremental sheet forming spisf from last three decades research on generative sheet metal manufacturing processes like deep drawing and single point incremental sheet forming spisf has seen tremendous development marciniak et al 2002 spisf originated from the spinning process with its capability of drawing sheets without using any die.

4 clamped sheet can move up and down one can clearly see from fig.

Incremental sheet metal forming in architecture previous next image building on previous and current work this research utilizes single point incremental forming spif and dual sided incremental forming dsif to produce mass customized double curved both positive and negative gaussian curvature three dimensional forms from sheet metal.

Mao engineering research center for net shape manufacturing erc nsm the ohio state university columbus oh usa.

4 that the sheet metal is restrained at two locations other than the clamping i e at one location by forming tool and the.

Generally the sheet is formed by a round tipped tool typically 5 to 20mm in diameter.